Pengaruh Warna Pelapis dan Ketebalan Lapisan Pada Proses Zinc Electroplating Terhadap Laju Korosi Baja AISI 1015

Abstract

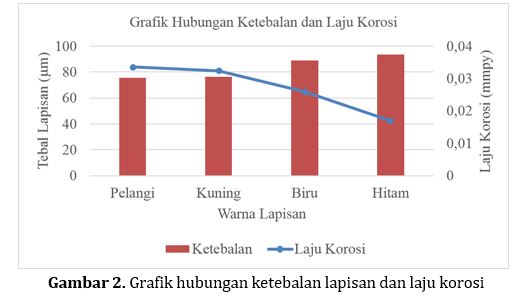

To improve the material's corrosion resistance, metal plating can be done. The main purpose of electroplating is to increase corrosion resistance and beautify the appearance with a variety of colors. The purpose of this study was to examine the effect of coating color variations on the corrosion rate of low carbon steel. The research method used was experimental. Using zinc electroplating and trivalent passivation treatment. Corrosion rate testing using the method weight loss, immersion period of 7 days with 3.5% NaCl corrosive medium. Layer thickness testing was carried out using the micro photo method. The research were obtained by directly observing the experimental results which were presented in tables and graphs. The results showed that there was an effect of coating color variations on the corrosion rate of AISI 1015 steel in the form of a decrease in the corrosion rate of each coating color variation. The lowest corrosion rate is in the black coating 0.016840030 mmpy. The layer thickness also affects the corrosion rate of AISI 1015 Steel. The higher the coating thickness in the process zinc electroplating , the lower the corrosion rate of AISI 1015 Steel.

References

ASTM, D 3039. Tensile Properties of Polymer Matrik Composite Materials. West Conshohocken, United States: ASTM International Standard.

Ferreira JR, J.M., Souza, K.P., Queiroz, F.M., Costa, I., and Tomachuk, C.R., 2016, Electrochemical And Chemical Characterization Of Electrodeposited Zinc Surface Exposed To New Surface Treatments, Surface & Coatings Technology, Vol. 294, pp. 36-46.

Haque, I. U., Sadiq, I., and Ahmad, N., 2003, Durability Of Passivation In Zinc Electroplating, Jour.Chem.Soc.Pak, Vol. 25, pp. 12-16.

Idora, M. S. N., Rahman, M. M., Ismail, M., and Wan Nik, W. B., 2014, Effect of Zinc Coating Thickness on Corrosion Performance of Mild Steel in Atmospheric and Seawater Environment Applied, Mechanics and Materials, Vol. 554, pp. 213-217.

Long, Z. L., Y. C. Zhou, L. Xiao., 2003, Characterization ff Black Chromate Conversion Coating On The Electrodeposited Zinc–Iron Alloy, Apllied Surface Science, Vol. 218, pp. 123-136.

Sandi, A. P., Suka, E.G., and Supriyatna, Y.I., 2017, Pengaruh Waktu Electroplating Terhadap Laju Korosi Baja Aisi 1020 dalam Medium Korosif Nacl 3%, JURNAL Teori dan Aplikasi Fisika, Vol. 5, pp. 205-212.

Setiawan, A., Indriyani, N.L., and Herawan, B., 2019, Pengaruh Arus dan Waktu Terhadap Lapisan Zinc Plating pada Material SGD400-D dengan Menggunakan Proses Electroplating, Jurnal Ilmiah Teknik Mesin, Vol. 7, pp. 32-39.

Sutrisno, Edi., 2012, Laju Korosi Lapisan Krom Pada Knalpot Berbahan Baja Karbon AISI 1010, Depok: Universitas Gunadarma.

Widodo, T. D., Raharjo, R., Kusumaningsih, H., Bintarto, R., Siswoyo, R. C., and Sasongko, M. N., 2019,Pengaruh Tegangan Dan Waktu Pada Proses Elektropolishing Terhadap Surface Roghness Material Stainless Steel Aisi 316L, Rekayasa Mesin, Vol. 10, pp. 309-316.