Analisa Produktivitas Mesin Dan Merancang Improvement Mesin Produksi Di Line Forming Fastener PT Dharma Polimetal

Abstract

Abstrak

__________________________________________________________________________________________

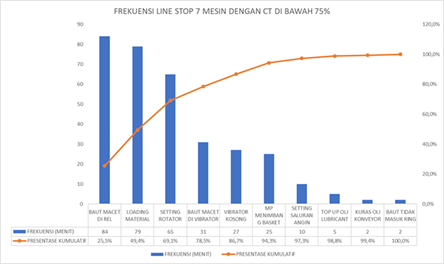

Tujuan penelitian ini adalah mengetahui tahapan alur produksi di Divisi Fastener PT Dharma Polimetal. Mengetahui tahapan proses forming dalam divisi Fastener PT Dharma Polimetal. Mengetahui permasalahan yang timbul di line forming Fastener PT Dharma Polimetal. Mengetahui penyebab akar permasalahan yang timbul di line forming Fastener PT Dharma Polimetal. Mengetahui rancangan rencana perbaikan untuk permasalahan di line forming Fastener PT Dharma Polimetal. Divisi Fastener merupakan salah satu bisnis produksi di PT Dharma Polimetal yang berfokus untuk memproduksi produk-produk pengencang. Untuk produk yang dihasilkan di Divisi Fastener ini antara lain Bolt Flange 6 mm, Bolt Torx m8 x 25 mm, Screw Tapp 5 x 12, Bolt Flange m10 x 190, dan lain-lain. Dengan dibuatnya penelitian ini peneliti dapat mengetahui produktivitas mesin di line forming di Divisi Fastener PT Dharma Polimetal, menganalisa faktor-faktor produksi yang mempengaruhi produktivitas line forming Divisi Fastener PT Dharma Polimetal, dan merumuskan rancangan perbaikan untuk meningkatkan produktivitas line forming Divisi Fastener PT Dharma Polimetal.

Abstract

__________________________________________________________________________________________

The purpose of this study was to determine the stages of the production flow in the Fastener Division of PT Dharma Polimetal. Knowing the stages of the forming process in the Fastener division of PT Dharma Polimetal. Knowing the problems that arise in the PT Dharma Polimetal Fastener line forming. Knowing the root cause of the problems that arise in the PT Dharma Polimetal Fastener line forming. Knowing the draft improvement plan for problems in the PT Dharma Polimetal Fastener line forming. The Fastener Division is one of the production businesses at PT Dharma Polimetal which focuses on producing fastener products. The products produced in the Fastener Division include Bolt Flange 6 mm, Bolt Torx m8 x 25 mm, Screw Tapping 5 x 12, Bolt Flange m10 x 190, and others. With this research, researchers were able to determine machine productivity in line forming in the Fastener Division of PT Dharma Polimetal, analyze the production factors that affect the productivity of line forming in the Fastener Division of PT Dharma Polimetal, and formulate improvement plans to increase the productivity of line forming in the Fastener Division of PT Dharma Polimetal.

References

2. Ramli, S. N. (2022) ‘Pengaruh Motivasi Dan Lingkungan Kerja Terhadap Kinerja’, Jurnal Ekonomi dan Sosial (INPUT), 2(2), p. 167.

3. Budiyanto, E., Yuono, L. D. and Rohman, F. (2020) ‘Analisa proses produksi part number D574-50081-201 menggunakan mesin milling CNC di PT DI’, Turbo : Jurnal Program Studi Teknik Mesin, 9(2). doi: 10.24127/trb.v9i2.1427.

4. Paundra, F., Bahtiar, Y. and Elmiawan, P. (2023) ‘Metode Perawatan Dan Perbaikan Mesin Creeper Di Pabrik Pengolah Karet PT. Perkebunan Nusantara VII Unit Rejosari’, 3(1), pp. 11–14.

5. Haryono, L., & Susanty, A. (2018). Penerapan Total Productive Maintenance Dengan Pendekatan Overall Equipment Effectiveness (OEE) dan Penentuan Kebijakan Maintenance Pada Mesin Ring Frame Divisi Spinning I DI PT Pisma Putra Textile. Industrial Engineering Online Journal, 6(4). Retrieved from https://ejournal3.undip.ac.id/index.php/ieoj/article/view/18274.

6. Akbar, Fajar. 2018. Analisa Peningkatan Prduktivitas Penggunaan Mesin Press Dengan Menggunakan Metode Data Envelopment Analysis Di PT. Keramik Diamond Industries Gresik. Teknik Mesin, FT, UNESA.

7. Rinawati, D. I. & Dewi, N. C. 2014. Analisis Penerapan Total Productive Maintenance (Tpm) Menggunakan Overall Equipment Efectiveness (Oee) Dan Six Big Losses Pada Mesin Cavitec Di Pt. Essentra Surabaya. Prosiding SNATIF Ke-1: 21-26.

8. Brown, Sarah. (2020) 'Enhancing Productivity in Manufacturing: A Case Study of Forming Fastener Production Line', Proceedings of the International Conference on Industrial Engineering and Operations Management, pp. 256-271.

9. Anderson, Robert. (2021) 'Design and Analysis of Production Line Improvements for Fastener Manufacturing', Journal of Manufacturing Systems, vol. 35, no. 4, pp. 112-128.

10. Gupta, Ravi. (2022) 'A Study on Productivity Enhancement in Forming Fastener Production Line', International Journal of Advanced Manufacturing Technology, vol. 48, no. 1-4, pp. 67-84.

Copyright (c) 2023 Jurnal Inovasi Mesin

This work is licensed under a Creative Commons Attribution 4.0 International License.