EFFECT OF VARIATION IMMERSION TIME FIBER HEMP COMPOSITE USING NaOH MATRIX POLYURETHANE ON TENSILE STRENGTH METHOD

DOI:

https://doi.org/10.15294/4sj3jr07Keywords:

Composite, Polyurethene, Compression Molding, Tensile Strength, NaOH, Hemp FiberAbstract

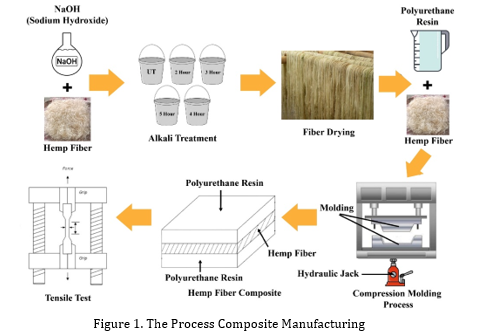

NaOH immersion treatment on hemp fiber is very important in making composites. This is because natural fibers still contain materials such as lignin and hemicellulose so hemp fibers are cleaner and can provide strong fiber and resin attachment. The aim of this research is to find out how the best time for soaking in NaOH for hemp fiber compares to the tensile strength of hemp fiber composites. The materials used are polyurethane and hemp fiber. The research focused on variations without treatment, 2 hours, 3 hours, 4 hours, and 5 hours with a percentage of 5% NaOH and dried under direct sunlight after soaking. Composite manufacture was carried out using the compression molding method for 24 hours with a pressure of 5 bar. Tensile testing was also used in this research with reference to the ASTM D 638 standard. The fiber surface experiences changes in shape such as cleanliness, color and fiber structure which are different in each variation. It should be noted that the maximum tensile strength is 11,597 MPa at 4 hours of immersion, and the lowest tensile strength is 6,054 MPa at 5 hours of immersion. Then the lowest modulus of elasticity value is found in the variation without treatment at 0,049 GPa. The highest value of elastic modulus is found in the 4 hour variation with a value of 0,076 GPa.