ANALYSIS OF MECHANICAL CHARACTERISTICS OF TOOTH BUCKET EXCAVATOR BASED ON DIFFERENT GRADE LEVELS

DOI:

https://doi.org/10.15294/jptm.v25i02.33074Keywords:

tooth bucket, vickers hardness, microstructure, martensite phase, ferrite phase.Abstract

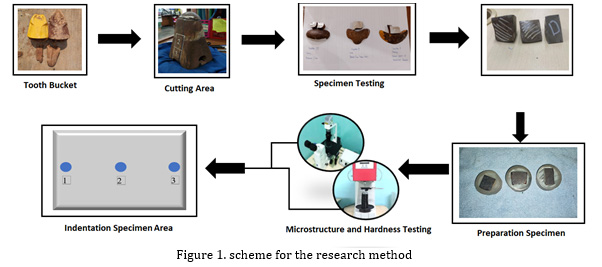

The purpose of this study is to comprehend the microstructure and hardness value of three distinct tooth bucket manufacturers. Three manufacturers' excavator tooth buckets—Canada Grade, China Grade A, and China Grade C—are compared for their mechanical characteristics. Among the tests are the Vickers method for measuring hardness, optical microscopy for examining microstructure, and chemical composition analysis. According to the results, the primary elements in all three specimens—carbon, silicon, manganese, and chromium—meet the DIN Grade 25CrMo4 standard. The martensite phase, which gives the Canada product its hardness and resistance to deformation, dominates its microstructure. The China Grade C product, on the other hand, has a more prominent ferrite phase, which raises ductility while decreasing hardness. China Grade C (570.24 HVN) had the highest hardness test value, followed by China Grade A (517.67 HVN) and Canada (468.09 HVN). This demonstrates that while Canada excels at withstanding heavy loads without damage, China Grade C is better suited for applications needing high wear resistance. Users of heavy machinery can use this study as a scientific guide when choosing bucket nails based on operational requirements, including material toughness and wear.