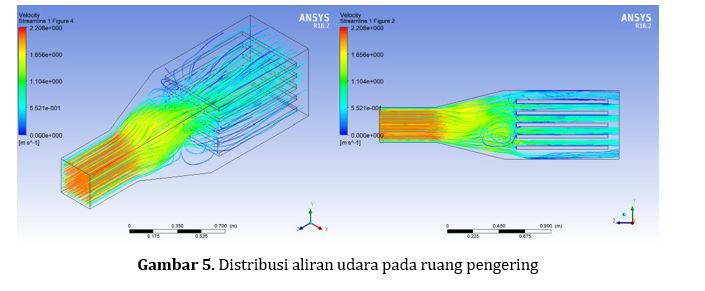

Analisis Aliran Udara Pada Ruang Pengering Low Temperature Dryer Dengan Simulasi CFD

Abstract

Food drying technology in maintaining food quality has become an attraction for the food industry. Low temperature drying was the option for drying food while maintaining the nutritional value of food remain intact. The purpose of this study was to determine the air and temperature distribution that occurred in the drying chamber using Computational Fluid Dynamic (CFD) simulations. Geometry of the drying chamber has been done previously in 3D design drawings using software. Various parameters for simulation have been used. The result showed air flowed unevenly in some shelves of drying chamber so that some adjustments were made to the geometry of the drying chamber. After several changes, the geometry of drying chamber could distribute air and heat flow evenly. The air flow into the drying chamber at 2 m/s dropped to 1 m/s upto 1,2 m/s when flow on the drying rack. While the initial air temperature of 50oC was distributed evenly on a drying rack with temperatures ranging from 45oC to 50oC.

References

Djaeni, M., & Sari, A. 2015. Low Temperature Seaweed Drying Using Dehumidified Air. Procedia Environmental Sciences 23: 2–10.

Putra, R. N., & Ajiwiguna, T. A. 2017. Influence of Air Temperature and Velocity for Drying Process. Procedia Engineering: 516–519.

Sekyere, C. K. K., Forson, F. K., & Adam, F. W. 2016. Experimental Investigation of The Drying Characteristics of A Mixed Mode Natural Convection Solar Crop Dryer With Back Up Heater. Renewable Energy: 532–542.

Sukamta. Thoharudin, Nugroho, D. M., 2018. Simulasi CFD Aliran Stratified Air-Udara pada Pipa Horisontal. Semesta Teknika, Vol. 21, No. 2: 206-215.

Trisnawati, W., Suter, K., Suastika, K., & Putra, N. K. 2014. Pengaruh Metode Pengeringan Terhadap Kandungan Antioksidan ,Serat Pangan dan Komposisi Gizi Tepung Labu Kuning 3(4): 135–14.

Ndeo, Y. P., Koehuan, V. A., & Bunnganaen, W. 2021. Simulasi Computational Fluid Dynamic (CFD) Rumah Pengering Kopi Menggunakan Plastik UltraViolet (UV) Solar Dryer. Jurnal Teknik Mesin 8(1): 11-20.

Fathurrahman, Syahrul, Nurchayati, Mirmanto, Sukmawaty, & Priyati, A. 2017. Pengaruh Temperatur dan Kecepatan Udara Terhadap Laju Pengeringan Jagung Pada Alat Fluidized Bed Dryer. SNMI XI: 272-278.

Misha, S., M. Sohif, H.R. Mohd, S. Kamaruzzaman, Elias S. 2013. The Prediction of Drying Uniformity in Tray Dryer System using CFD Simulation. International Journal of Machine Learning and Computing 3(5): 419-423.

Versteeg, H.K., W. Malalasekera. 1995. An Introduction to Computational Fluid Dynamics The Finite Volume Method. Longman Sc & Technical. Malaysia.