PENGARUH WAKTU EKSTRUKSI BAHAN EVAPORATION BOATS, GRAFIT DAN SEMEN CASTABLE PADA MESIN EKSTRUDER TERHADAP DENSITAS, POROSITAS DAN KEKUATAN IMPAK

Abstract

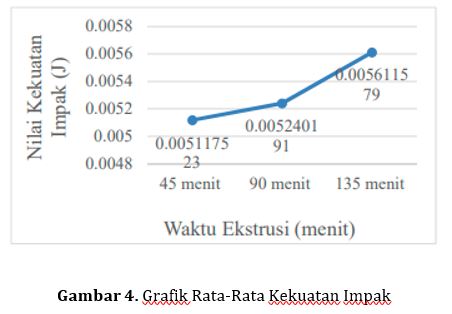

Waste is one of the main problems in Indonesian industry. The utilization of metal waste is very much needed by the metal smelting industry to melt and reshape to become goods that have more selling value. There are many kinds of waste obtained from the metallurgical manufacturing industry, one of which is material evaporation boats. Refractory materials commonly used for crucibles have not yet produced good refractories and the price is still expensive, so research on Evaporation Boats is needed for more utilization and advantages. This study aims to determine the effect of the extrusion time of evaporation boats, graphite and castable cement on the density, porosity, and impact strength of crucible materials. Variations in extrusion time used in this study were 45 minutes, 90 minutes and 135 minutes. The materials used are 70% evaporation boats by weight, 15% graphite, 15% castable cement, and mixed with 15% water of the total weight. The test results showed the highest density value was 2.05 g/cm3 at an extrusion time of 135 minutes, and the lowest was 2.03 g/cm3 at an extrusion time of 45 minutes. The highest porosity value was 5.5% at an extrusion time of 45 minutes, and the lowest was 2.4% at an extrusion time of 135 minutes. The highest impact strength value was 0.005611579 J at an extrusion time of 135 minutes, and the lowest was 0.005117523 J at an extrusion time of 45 minutes. From the resulting data, it is known that 1.) there is an effect of extrusion time on the density value. The longer the extrusion time, the higher the density value. 2.) There is an effect of extrusion time on the porosity value. The faster the extrusion time, the higher the porosity value. 3.) There is an effect of extrusion time on the impact strength. The longer the extrusion time, the higher the impact.

References

Jannah, E. M. (2020). Pengaruh Temperatur Sintering Terhadap Densitas,Porositas, dan Kekerasan Berbahan Evaporation Boats, Kaolin dan Semen Castable Sebagai Material Crucible. Semarang: Universitas Negeri Semarang.

Nurrohmah, S. I. (2019). Pengaruh Thermal Shock dan Komposisi Grafit,Kaolin (Clay) Terhadap Struktur Makro dan Ketahanan Impact Kowi Berbahan Dasar Limbah Evaporation Boats. Semarang: Universitas Negeri Semarang.

Oner, M., Kizil, G., Keskin, G., Bohatier, C. P., & Bechelany, M. (2018). The Effect of Boron Nitride on the Thermal and Mechanical Properties of Poly (3-Hydroxybutyrateco-3-hydroxyvalerate). Nanomaterials, 1-20.

Rahmadika, B. (2017). Pengaruh Pengurangan Setting Time (Wait On Cement) Pada Semen Tahan Api Dengan Penambahan Oil Well Cement. Balunijuk: Universitas Bangka Belitung.

Josep E. dkk. 1984. Perencanaan Teknik Mesin Edisi Keempat Jilid 2. Jakarta: Erlangga.

Tenaya. I. G. N. P., Sukadana. I. G. K., dan Pratama. I. G. N. B. S. 2013. Pengaruh Pemanasan Bahan Bakar terhadap Unjuk Kerja Mesin. Jurnal Energi dan Manufaktur 6/2: 105-114

Wilastri, S., Bayuseno, A., & Nugroho, S. (2011). Pengaruh Variasi Kecepatan Putar Dalam Metode Stir Casting Terhadap Densitas dan Porositas Al-SiC Untuk Aplikasi Blok Rem Kereta Api. Momentum, 31-35.

Karthich. R. Raja, dan Rio Melvin Aro.T, dan Shyam Shankar.M.B, dan Vinoth.M. 2014. Design and Optimization of Valveless Pulsejet Engine. IJERA. Chennai. Vol 4 hal 56-59.

Widarto, Wijananka, B. S., dan Paryanto. 2008. Teknik Pemesinan untuk Mengah Kejuruan. Jakarta: Direktorat Jendral Manajemen Pendidikan Dasar dan Menengah