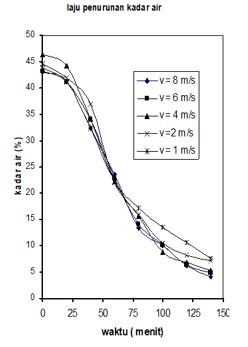

Pengaruh Variasi Kecepatan Sirkulasi Udara Terhadap Laju Pengeringan Kayu Pada Dapur Pengering Kayu

Abstract

The aim of this research is to investigate the effect of air circulation speed variations on the rate of wood drying in the wood drying kiln. The research was carried out by installing an exhaust fan at the end of the chimney exiting the oven. The speed of the exhaust fan can be varied. Variations in circulation speed are set from 1 m/s to 8 m/s. The temperature and RH in the oven at each drying stage are maintained stable. The results obtained from the research are as follows. The sample drying rate with four pieces of mahogany wood was found to be an average of 16.6% per hour for all variations. At the greatest speed variation Vcirculation = 8 m/s, the target final moisture content (MC) reaches 4.17%, and at Vcirculation = 1 m/s (lowest), the final MC is 7.67%. So the higher the circulation speed, the greater the drying rate. However, at high circulation speeds, physical damage to the wood will occur, namely cracks on the face and ends of the wood.

References

Incropera, Frank P., De Witt., David, 1985, Fundamentals of Heat and Mass Transfer, 2nd Edition, McGraw-Hill, New York.

Jasjfi E (terjemahan)., 1994, Perpindahan Kalor, Edisi Keenam, Erlangga, Jakarta.

Jiali Zhang; Lijie Qu; Zhenyu Wang; Zijian Zhao; Zhengbin He; Songlin Yi, 2017, Simulation And Validation Of Heat Transfer During Wood Heat Treatment Process. Results in Physics. Vol. 7 pp 3806-3812

Karnowo, Anis, S., Basyirun.(2008). Rekayasa Dapur Pengering Oven Kayu. Laporan Penlitian Hibah Bersaing

Kjell Suadicani; Niels Heding. 1992. Wood preparation, storage, and drying. Biomass and Bioenergy. Vol.2 pp. 149-156

Moran, Michael J., Howard N., Saphiro, 1995, Fundamental Of Engineering Thermodinamics, 3 rd Edition, John Wiley & Sons. Inc, Canada.

McCurdy, M.; Pang, S.; Keey, R..2015. Experimental Determination Of The Effect Of Temperature And Humidity On The Development Of Colour In Pinus Radiata. Brazilian Journal of Chemical Engineering. Vol 22 pp 323-367

Necati, Ozisik M., 1981, Basic Heat Transfer, 2 nd Edition, McGraw-Hill, New York.

Sun, Z.F.; Carrington, C.G.; .Bannister, P. 2000. Dynamic Modelling of the Wood Stack in a Wood Drying Kiln. Chemical Engineering Research and Design. Vol.78, pp 107-117

Terehovics, E; Veidenbergs, I; Blumberga, D. 2017. Energy and exergy balance methodology. Wood chip dryer. Energy Procedia. Vol. 128 Pages 551-557

Yan Qing; Ming Liu; Yiqiang Wu; Shanshan Jia; Shuang Wang; Xin gong., 2017. Investigation On Stability And Moisture Absorption Of Superhydrophobic Wood Under Alternating Humidity and Temperature Conditions. R. in Physics. Vol 7, pp 1705-1711